The demand for efficient and reliable power distribution systems in commercial spaces is skyrocketing in today’s fast-paced world. From bustling shopping malls to high-tech office complexes, the lifeline of these structures is a seamless supply of electricity. Here’s where commercial busways make a grand entry as the modern-day champions of electrical distribution. What exactly is…

Read more

In September 2007, Jim Ozzello and Phil Delavy decided to take their combined 38 years of experience and form J&P Electrical Company. In 2012, Jason Ozzello officially became a co-owner of the company. Since Phil’s retirement, J&P has been a family-owned and operated business; owners Jason and Jim and brothers David and Jacob all work with…

Read more

Busway and bus duct power distribution systems are used in both commercial and industrial situations to transmit electrical power safely and efficiently from the source to the loads. Delivering flexible and reliable power dispersal, they differ in construction, installation, and application. In 2021, the global busway- duct market size was valued at $12.1 billion. By…

Read more

Isolated-Phase Bus (IPB) systems are vital in transferring bulk electricity through the grid. For decades, IPBs have been centered around the original designs from General Electric (GE) and Westinghouse, which led the industry. Now, improvements to insulators, mountings, and housings have elevated the model, making them even more reliable. IPBs transfer a power plant’s heavy…

Read more

The anaerobic adhesives market is set to reach $738.32 million by 2026 and was valued at $461.8 million in 2018, making the CAGR from 2019 to 2026 estimated at 6.01 percent. But what are these mysterious adhesives? Read on to find out. The definition of “anaerobic” is the absence of air. So anaerobic adhesives require…

Read more

The United States federal government is slated to deliver heavy funding for infrastructure projects in the upcoming years. The onshoring boom starting to take hold makes it a better time than ever to invest in specific stocks focused on infrastructure. The infrastructure law will boost the funding of many American infrastructure companies as a growing…

Read more

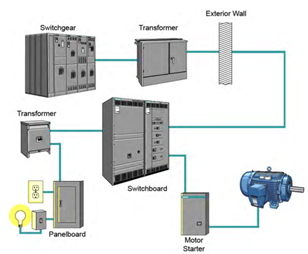

A building’s electrical system is a complex and critical infrastructure few know much about. Most people take advantage of flipping a switch and receiving automated light or functionality from a machine without much consideration of how it occurs. This blog introduces a few major products that make it all possible: panelboards, switchboards, and switchgear. …

Read more

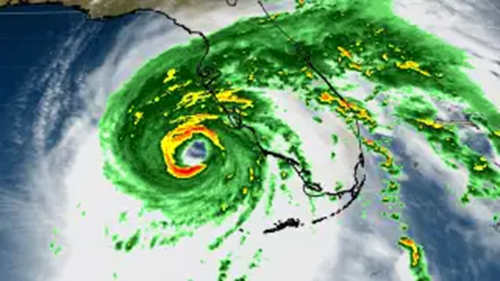

Florida’s power grid was recently demolished by Category 4 Hurricane Ian, and crews are furiously rebuilding using poles, generators, and wire. Hurricane Ian was one of the strongest storms ever to hit the United States and the deadliest to hit Florida since 1935. The catastrophic losses totaled tens of billions of dollars, killing more than…

Read more

A safety switch (or disconnect) monitors the electric current in various applications. They are used with major industrial machines such as conveyor belts, line equipment, heavy appliances, and whole-system electrical protection. You may need to disconnect your equipment from the electrical supply for repairs, maintenance, or emergencies. Safety switches monitor the current and detect faults…

Read more